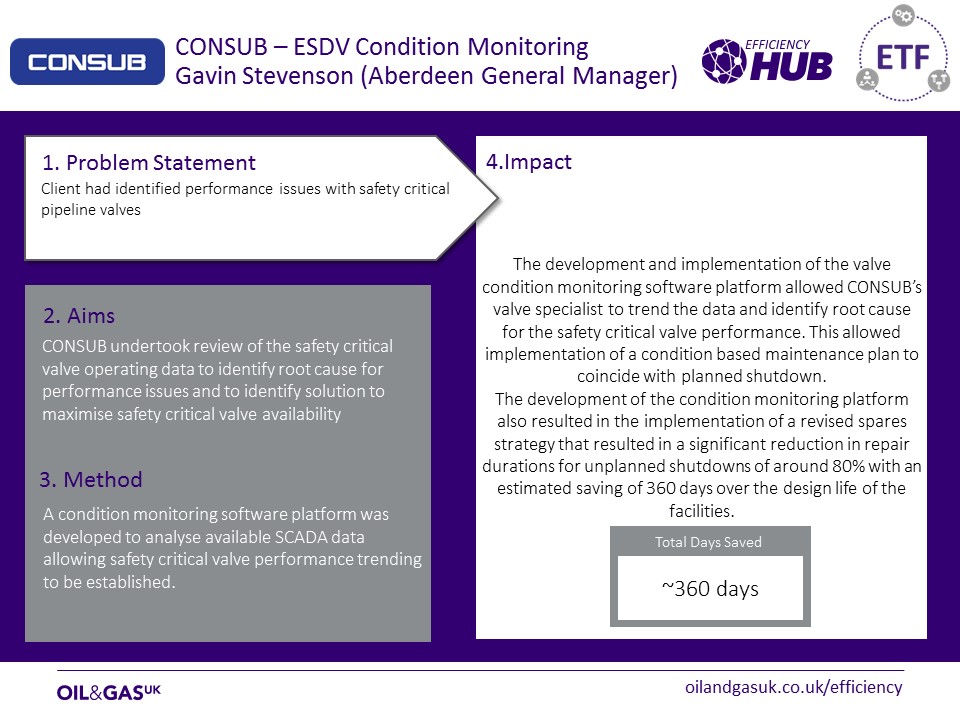

CONSUB – ESDV Condition Monitoring

Problem Statement

Client had identified performance issues with safety critical pipeline valves.

Aims

CONSUB undertook review of the safety critical valve operating data to identify root cause for performance issues and to identify solution to maximise safety critical valve availability

Method

A condition monitoring software platform was developed to analyse available SCADA data allowing safety critical valve performance trending to be established.

Impact

The development and implementation of the valve condition monitoring software platform allowed CONSUB’s valve specialist to trend the data and identify root cause for the safety critical valve performance. This allowed implementation of a condition based maintenance plan to coincide with planned shutdown.

The development of the condition monitoring platform also resulted in the implementation of a revised spares strategy that resulted in a significant reduction in repair durations for unplanned shutdowns of around 80% with an estimated saving of 360 days over the design life of the facilities.

Total Savings Anticipated

360 days saved

Click on the image above to download the case study.