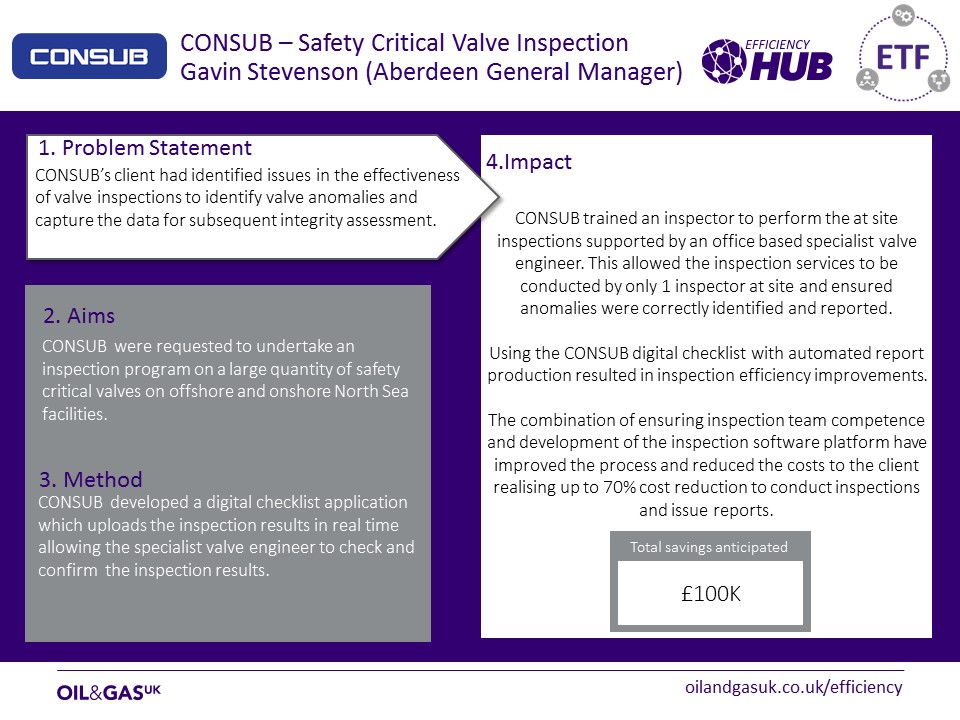

CONSUB – Safety Critical Valve Inspection

Problem Statement

CONSUB’s client had identified issues in the effectiveness of valve inspections to identify valve anomalies and capture the data for subsequent integrity assessment.

Aims

CONSUB were requested to undertake an inspection program on a large quantity of safety critical valves on offshore and onshore North Sea facilities.

Method

CONSUB developed a digital checklist application which uploads the inspection results in real time allowing the specialist valve engineer to check and confirm the inspection results.

Impact

CONSUB trained an inspector to perform the at site inspections supported by an office based specialist valve engineer. This allowed the inspection services to be conducted by only 1 inspector at site and ensured anomalies were correctly identified and reported.

Using the CONSUB digital checklist with automated report production resulted in inspection efficiency improvements.

The combination of ensuring inspection team competence and development of the inspection software platform have improved the process and reduced the costs to the client

realising up to 70% cost reduction to conduct inspections and issue reports.

Total Savings Anticipated

£100,000 estimated.

Click on the image above to download the case study.