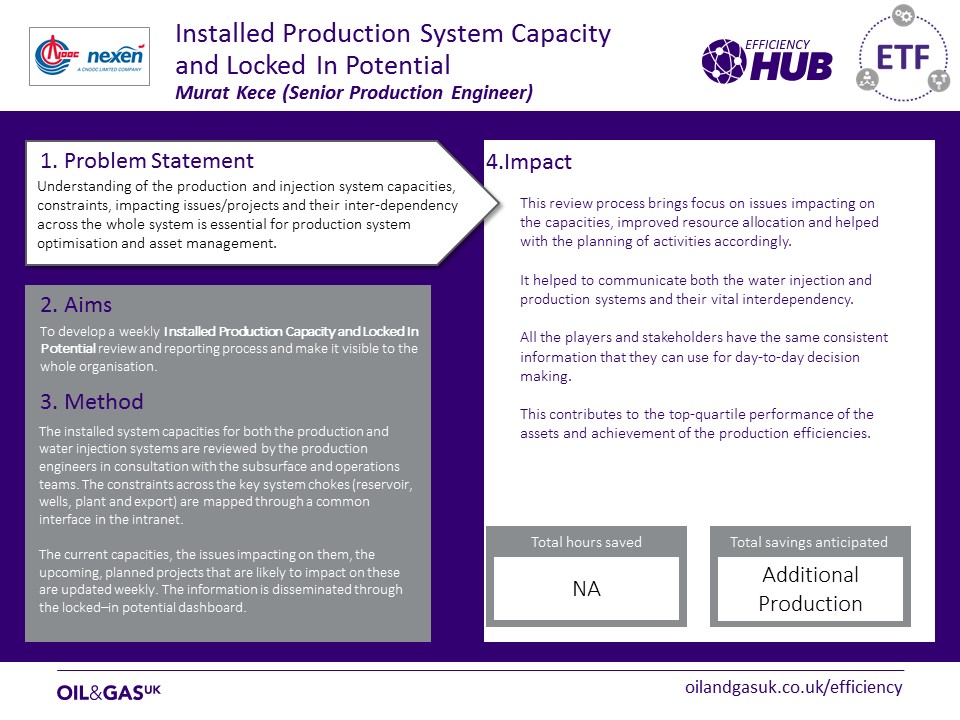

Nexen – Installed Production System Capacity and Locked In Potential

Problem Statement

Understanding of the production and injection system capacities, constraints, impacting issues/projects and their inter-dependency across the whole system is essential for production system optimisation and asset management.

Aims

To develop a weekly Installed Production Capacity and Locked In Potential review and reporting process and make it visible to the whole organisation.

Method

The installed system capacities for both the production and water injection systems are reviewed by the production engineers in consultation with the subsurface and operations teams. The constraints across the key system chokes (reservoir, wells, plant and export) are mapped through a common interface in the intranet.

The current capacities, the issues impacting on them, the upcoming, planned projects that are likely to impact on these are updated weekly. The information is disseminated through the locked–in potential dashboard.

This review process brings focus on issues impacting on the capacities, improved resource allocation and helped with the planning of activities accordingly.

It helped to communicate both the water injection and production systems and their vital interdependency.

All the players and stakeholders have the same consistent information that they can use for day-to-day decision making.

This contributes to the top-quartile performance of the assets and achievement of the production efficiencies.

Total Savings Anticipated

Additional Production

Click on the image above to download the case study.