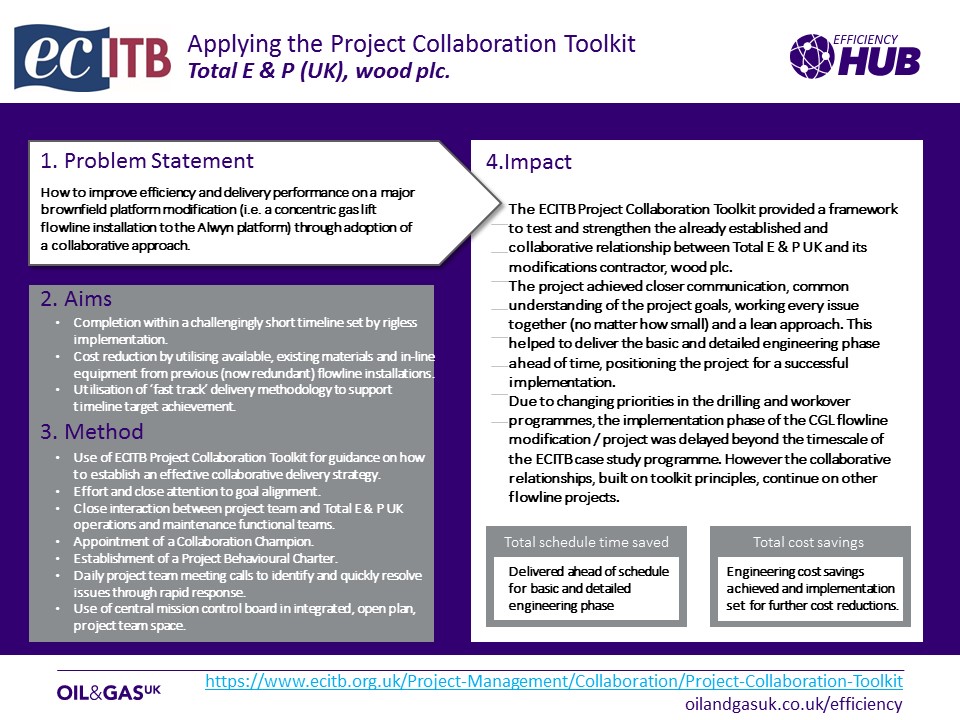

ECITB – Applying the Project Collaboration Toolkit Total E & P (UK), Wood plc.

Problem Statement

How to improve efficiency and delivery performance on a major brownfield platform modification (i.e. a concentric gas lift flowline installation to the Alwyn platform) through adoption of a collaborative approach.

Aims

- Completion within a challengingly short timeline set by rigless implementation.

- Cost reduction by utilising available, existing materials and in-line equipment from previous (now redundant) flowline installations.

- Utilisation of ‘fast track’ delivery methodology to support timeline target achievement.

Method

- Use of ECITB Project Collaboration Toolkit for guidance on how to establish an effective collaborative delivery strategy.

- Effort and close attention to goal alignment.

- Close interaction between project team and Total E & P UK operations and maintenance functional teams.

- Appointment of a Collaboration Champion.

- Establishment of a Project Behavioural Charter.

- Daily project team meeting calls to identify and quickly resolve issues through rapid response.

- Use of central mission control board in integrated, open plan, project team space.

Impact

- The ECITB Project Collaboration Toolkit provided a framework to test and strengthen the already established and collaborative relationship between Total E & P UK and its modifications contractor, wood plc.

- The project achieved closer communication, common understanding of the project goals, working every issue together (no matter how small) and a lean approach. This helped to deliver the basic and detailed engineering phase ahead of time, positioning the project for a successful implementation.

- Due to changing priorities in the drilling and workover programmes, the implementation phase of the CGL flowline modification / project was delayed beyond the timescale of the ECITB case study programme. However the collaborative relationships, built on toolkit principles, continue on other flowline projects.

Total Savings Anticipated

Delivered ahead of schedule for basic and detailed engineering phase.

Engineering cost savings achieved and implementation set for further cost reductions.

Click on the image above to download the case study.