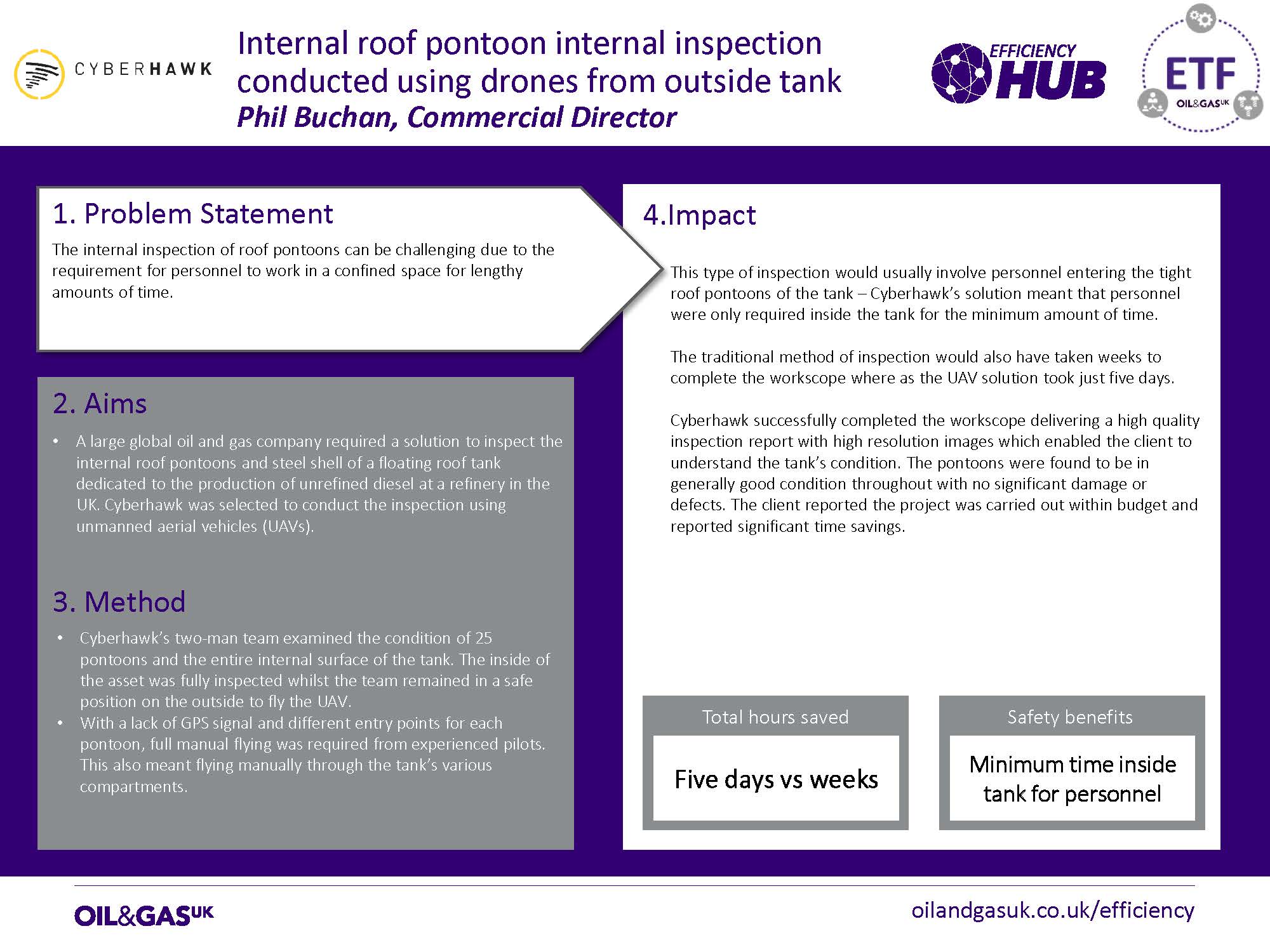

Cyberhawk – Internal roof pontoon internal inspection conducted using drones from outside tank

Problem Statement

The internal inspection of roof pontoons can be challenging due to the requirement for personnel to work in a confined space for lengthy amounts of time.

Aims

A large global oil and gas company required a solution to inspect the internal roof pontoons and steel shell of a floating roof tank dedicated to the production of unrefined diesel at a refinery in the UK. Cyberhawk was selected to conduct the inspection using unmanned aerial vehicles (UAVs).

Method

Cyberhawk’s two-man team examined the condition of 25 pontoons and the entire internal surface of the tank. The inside of the asset was fully inspected whilst the team remained in a safe position on the outside to fly the UAV.

With a lack of GPS signal and different entry points for each pontoon, full manual flying was required from experienced pilots. This also meant flying manually through the tank’s various compartments.

This type of inspection would usually involve personnel entering the tight roof pontoons of the tank – Cyberhawk’s solution meant that personnel were only required inside the tank for the minimum amount of time.

The traditional method of inspection would also have taken weeks to complete the workscope where as the UAV solution took just five days.

Cyberhawk successfully completed the workscope delivering a high quality inspection report with high resolution images which enabled the client to understand the tank’s condition. The pontoons were found to be in generally good condition throughout with no significant damage or defects. The client reported the project was carried out within budget and reported significant time savings.

Total hours saved

Five days vs weeks

Safety benefits

Minimum time inside for personnel

Click on the image above to download the case study.