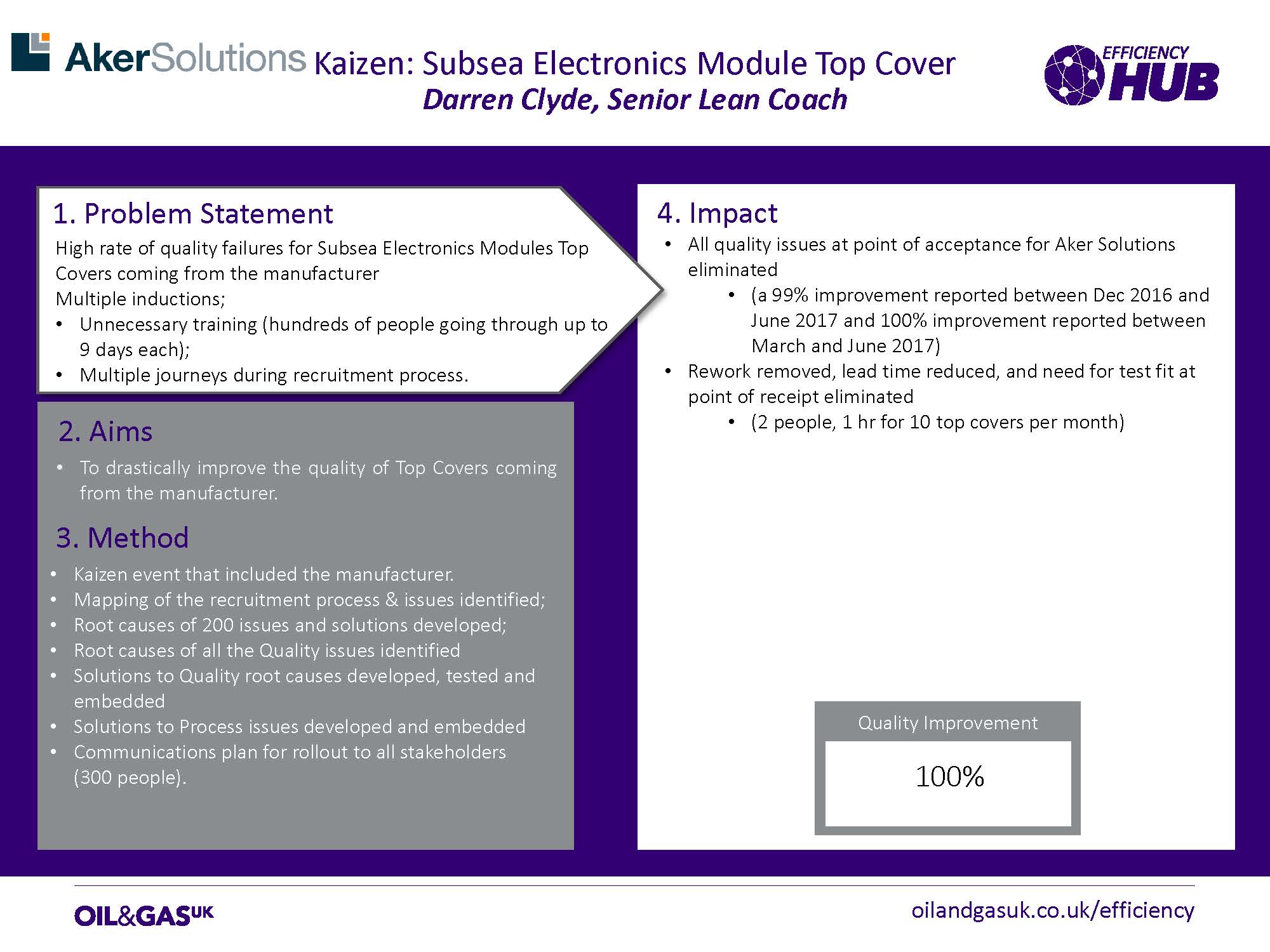

Aker Solutions – Kaizen: Subsea Electronics Module Top Cover

1. Problem Statement

High rate of quality failures for Subsea Electronics Modules Top Covers coming from the manufacturer

Multiple inductions;

• Unnecessary training (hundreds of people going through up to 9 days each);

• Multiple journeys during recruitment process.

2. Aims

•To drastically improve the quality of Top Covers coming from the manufacturer

3. Method

- Kaizen event that included the manufacturer.

- Mapping of the recruitment process & issues identified;

- Root causes of 200 issues and solutions developed

- Root causes of all the Quality issues identified

- Solutions to Quality root causes developed, tested and embedded

- Solutions to Process issues developed and embedded

- Communications plan for rollout to all stakeholders

(300 people).

4. Impact

- All quality issues at point of acceptance for Aker Solutions eliminated

- (a 99% improvement reported between Dec 2016 and June 2017 and 100% improvement reported between March and June 2017)

- Rework removed, lead time reduced, and need for test fit at point of receipt eliminated

- (2 people, 1 hr for 10 top covers per month)

Quality Improvement

100%

Submitted by Darren Clyde, Senior Lean Coach, Aker Solutions

Click on the image above to download the case study.