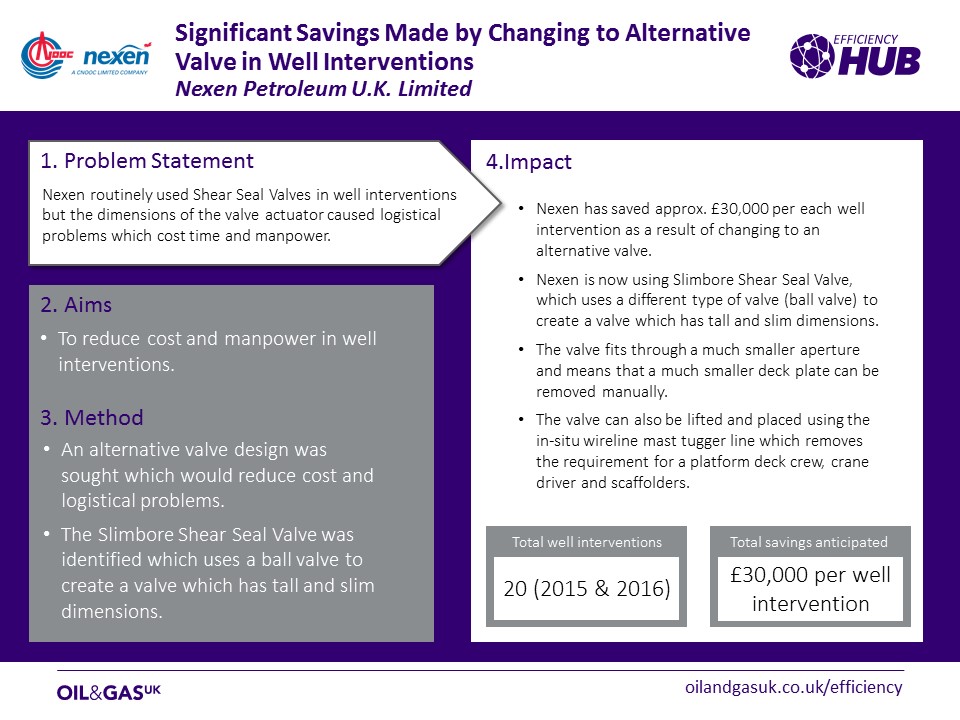

Nexen – Significant savings made by changing to alternative valve in well interventions

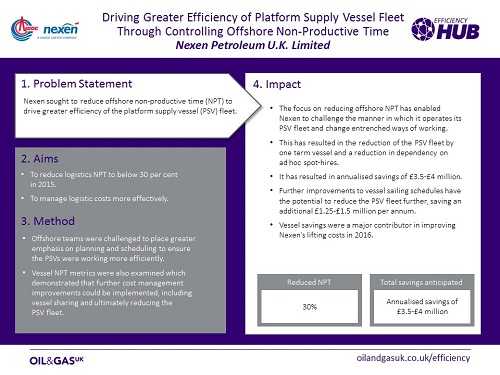

Problem statement

Nexen routinely used Shear Seal Valves in well interventions but the dimensions of the valve actuator caused logistical problems which cost time and manpower.

Aims

To reduce cost and manpower in well interventions.

Method

- An alternative valve design was sought which would reduce cost and logistical problems.

- The Slimbore Shear Seal Valve was identified which uses a ball valve to create a valve which has tall and slim dimensions.

Impact

- Nexen has saved approx. £30,000 per each well intervention as a result of changing to an alternative valve.

- Nexen is now using Slimbore Shear Seal Valve, which uses a different type of valve (ball valve) to create a valve which has tall and slim dimensions.

- The valve fits through a much smaller aperture and means that a much smaller deck plate can be removed manually.

- The valve can also be lifted and placed using the in-situ wireline mast tugger line which removes the requirement for a platform deck crew, crane driver and scaffolders.

Total well interventions 20 (2015 & 2016)

Total savings anticipated £30,00o per well intervention

Click on the image above to download the case study.