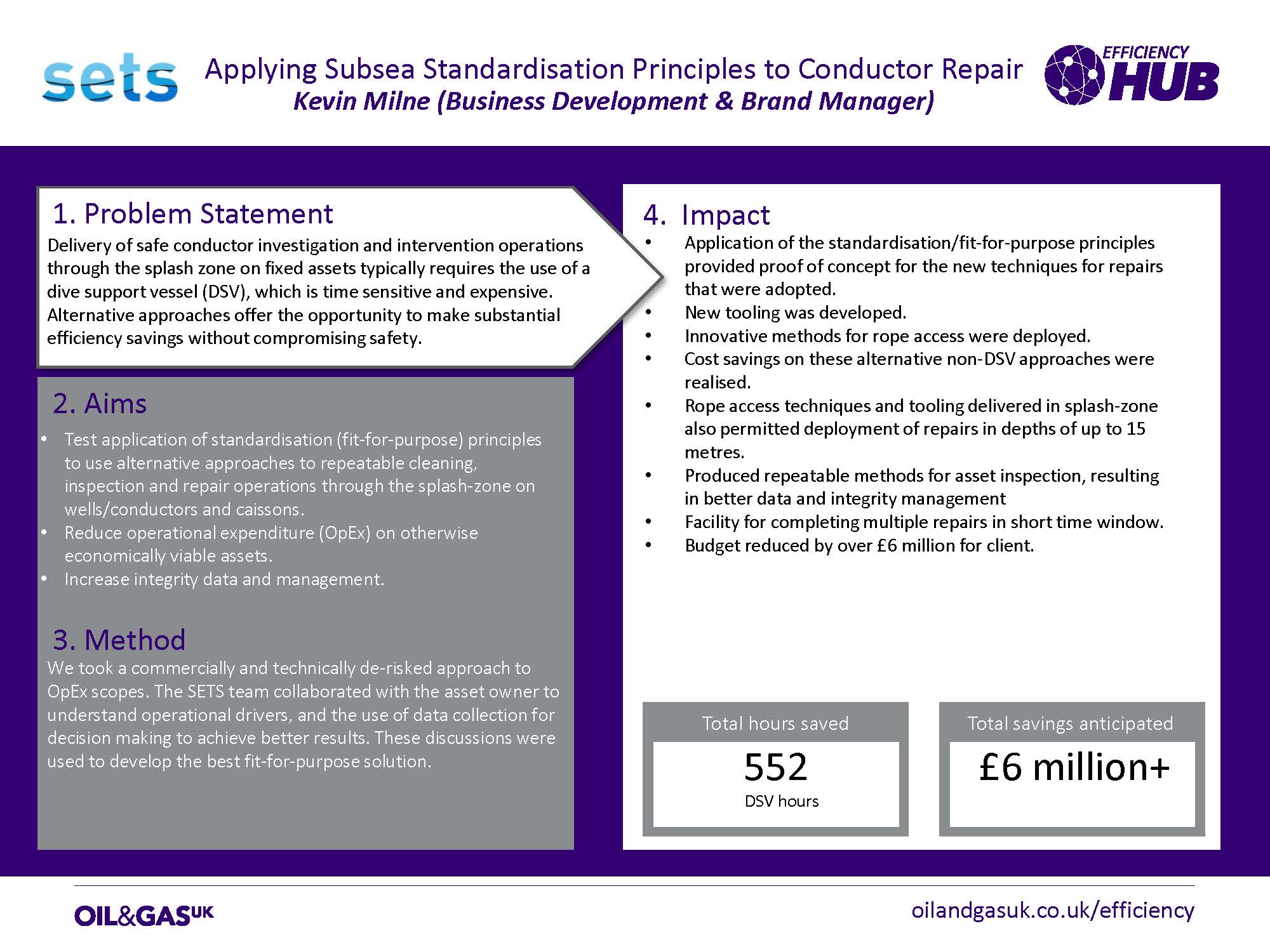

SETS – Applying subsea standardisation principles to conductor repair

Submitted by Kevin Milne (Business Development & Brand Manager)

Problem statement

Delivery of safe conductor investigation and intervention operations through the splash zone on fixed assets typically requires the use of a dive support vessel (DSV), which is time sensitive and expensive. Alternative approaches offer the opportunity to make substantial efficiency savings without compromising safety.

Aim

- Test application of standardisation (fit-for-purpose) principles to use alternative approaches to repeatable cleaning, inspection and repair operations through the splash-zone on wells/conductors and caissons.

- Reduce operational expenditure (OpEx) on otherwise economically viable assets.

- Increase integrity data and management.

Method

We took a commercially and technically de-risked approach to OpEx scopes. The SETS team collaborated with the asset owner to understand operational drivers, and the use of data collection for decision making to achieve better results. These discussions were used to develop the best fit-for-purpose solution.

Impact

- Application of the standardisation/fit-for-purpose principles provided proof of concept for the new techniques for repairs that were adopted.

- New tooling was developed.

- Innovative methods for rope access were deployed.

- Cost savings on these alternative non-DSV approaches were realised.

- Rope access techniques and tooling delivered in splash-zone also permitted deployment of repairs in depths of up to 15 metres.

- Produced repeatable methods for asset inspection, resulting in better data and integrity management

- Facility for completing multiple repairs in short time window.

- Budget reduced by over £6 million for client.

Total hours saved: 552 DSV hours

Total savings anticipated: £6 million+

Click on the image above to download the case study.